Manufacturing and Service

Products Sourcing/Equivalents

Here at EMTL we have developed very strong relationships with leading manufacturing and service companies all around the world. We can provide genuine branded parts as well as very competitive equivalents, our technical department have a wealth of knowledge to be able to assist you with any issues you may be facing sourcing components. Whilst some may think that using an equivalent will degrade performance or reliability, we see this as an opportunity to improve both aspects. We try to work closely with our customers to find out exactly what they need and get the most important parameters written into the specifications to allow improvement and continued reliability whilst also trying to reduce the costs.

Why Choose us

Wound Components

East Manufacturing Technologies Ltd can manufacture wound components on ferrite cores to meet your specific requirements. Standard used cores are Toroids, RM Cores, ETD Cores, E Cores, Rods, U Cores, Pot cores.

Typical products manufacture are:

• Common Mode Chokes

• Pulse Transformers

• Flyback Transformers

• Antennas

• Power Transformers

East Manufacturing Technologies Ltd can manufacture wound products on all standard lamination cores or toroid’s, up to 500 VA. Standard used cores are toroid’s, E cores and C Cores.

Typical products manufacture are:

• Current Transformers

• Hall Effect Sensors

• Encapsulated Transformers

• 3 Phase Transformers

• Power Transformers

East Manufacturing Technologies Ltd distribute a range of inductive SMD components, many equivalents to the Coilcraft range,

Typical products manufactured are:

• SMD Inductors

• Impeders

• Chips

• Beads

• Transformers

East Manufacturing Technologies Ltd now offer more solutions to our customers. Using our highly attentive eye to detail we have incorporated more services to assist the needs of our customers. Typical Assemblies manufacture include:

• Magnet Assemblies

• Box Builds

• Wound Assemblies

• Ferrite Grinding

• Cable Looms

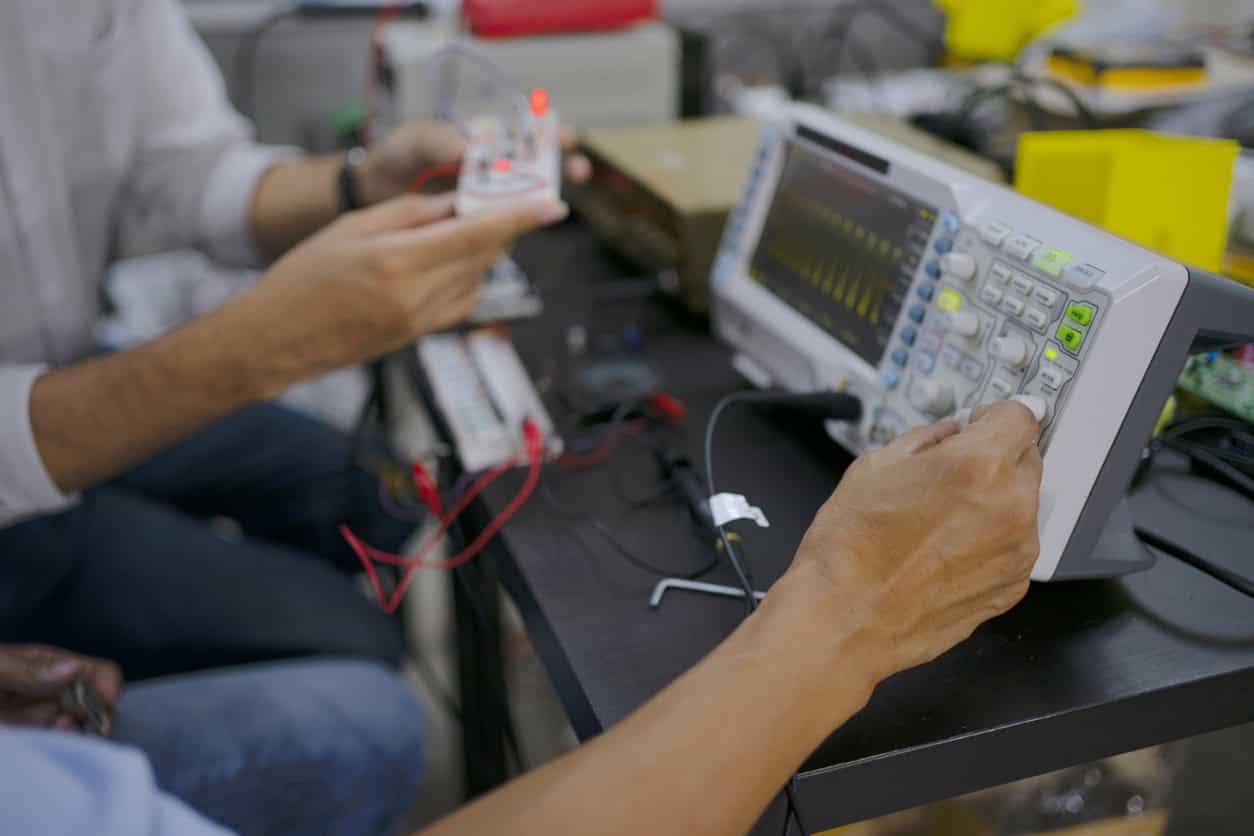

Product Design & Testing

EMTL take great pride in the products we supply, every product is batch tested in the UK, through our ISO approved quality checks. We have the following test equipment at our UK facility, Impedance Analyser, six Multi Frequency LCR meters, Test Oven, Hi-Pot Tester, DC ohm meter, Q meter, VAW Meters and RF amplifier. With expert knowledge we can even design products to meet customer specifications or suggest how to improve current designs. Our engineering department have a wealth of knowledge on the components we supply, we specialise in magnetic materials.

EMTL have two Jones & Shipman grinding machines at our UK office allowing us to gap to customer requirements and offer a rapid delivery service. We can grind to specific gaps or inductance values and offer modifications on core heights. We also offer precision grinding through one of our subcontractors. EMTL have a vast range of test equipment which allows us to test and measure all ground cores and ensure our customers get exactly what they need.