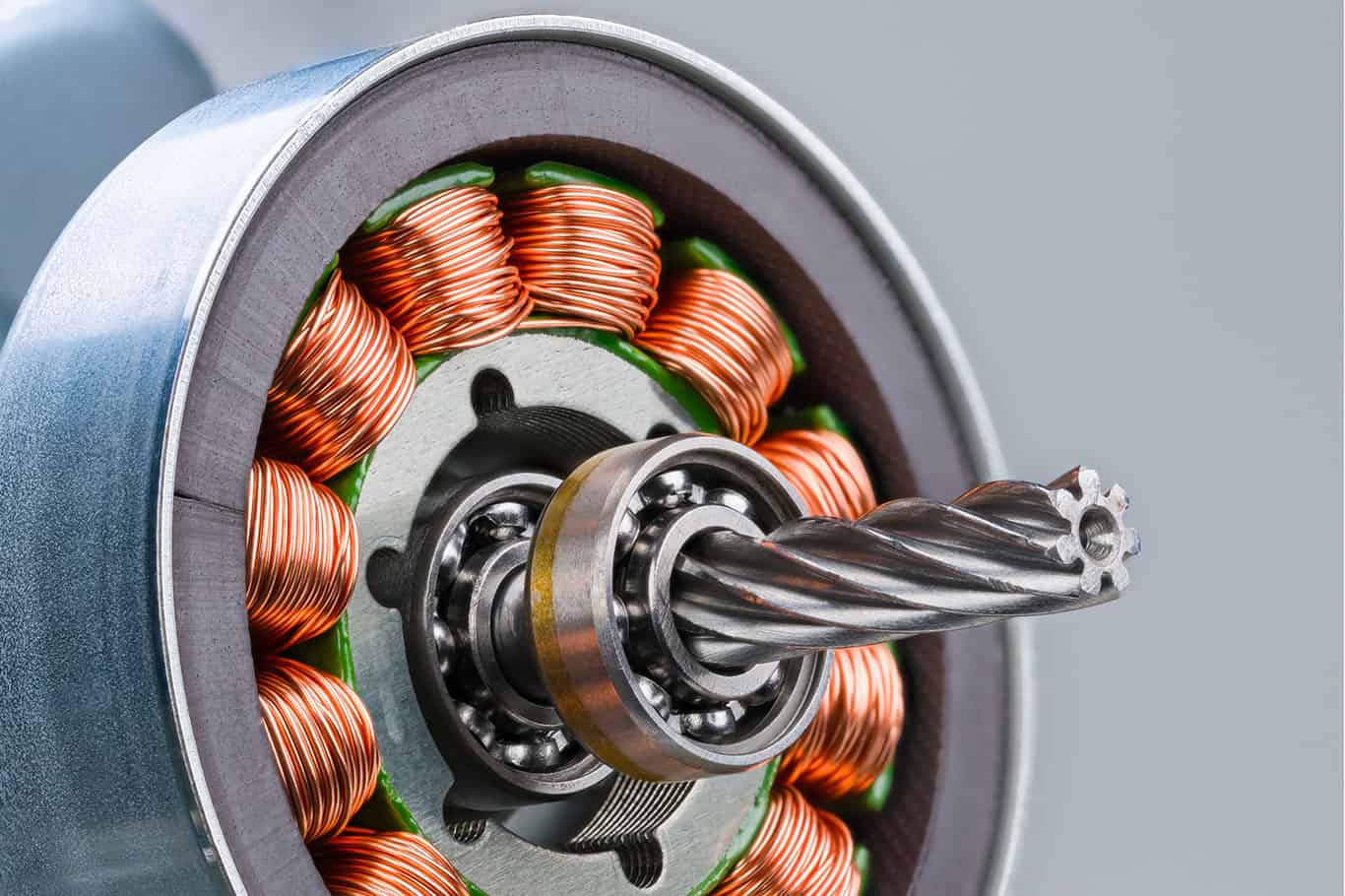

In the world of modern electronics, managing electrical interference and ensuring efficiency are critical concerns, especially in high-frequency power applications. A ferrite ring, often overlooked, plays a vital role in achieving this balance. By suppressing electromagnetic interference (EMI) and enhancing power quality, these rings are essential components for devices such as transformers, inductors, and power supplies. But why exactly are these magnetic materials so indispensable? This blog explores the importance of these rings and their key applications in high-frequency power systems.

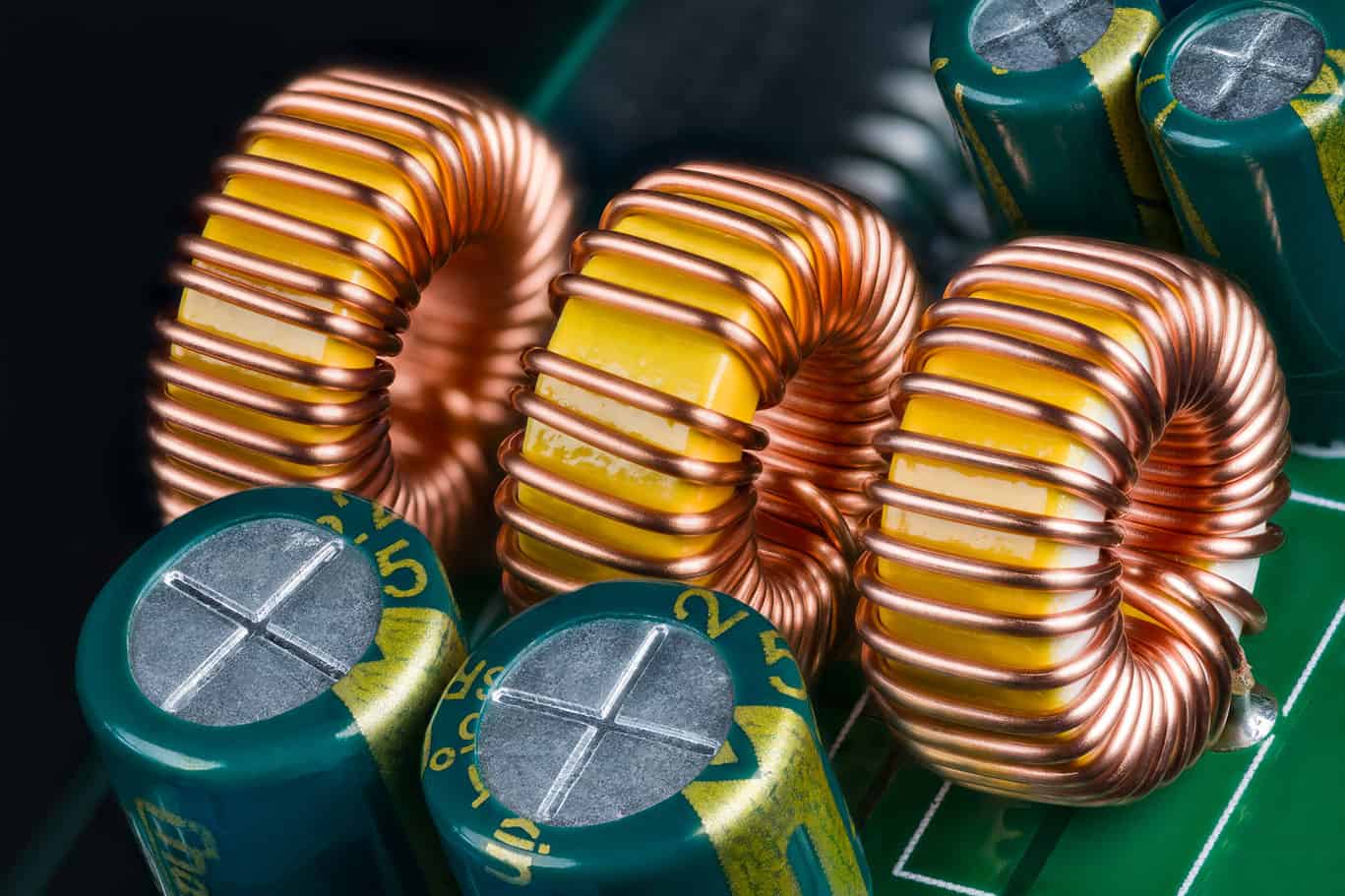

What Are Ferrite Rings?

Ferrite rings, also known as ferrite cores, are composed of soft ferrite materials that exhibit high magnetic permeability and low electrical conductivity. This unique combination allows them to absorb and dissipate high-frequency noise while maintaining the flow of low-frequency signals. The rings are commonly used to suppress unwanted electromagnetic waves that can disrupt the performance of sensitive electronics.

How Ferrite Rings Minimise EMI

In high-frequency power applications, controlling electromagnetic interference is crucial. These rings serve as passive filters that minimise high-frequency noise by acting as inductive components. When placed around a cable or wire, they absorb the EMI generated by switching devices, transformers, and power inverters. This effectively reduces signal distortion and prevents electrical noise from being emitted into surrounding components or the environment.

Key Benefits of EMI Reduction with Ferrite Rings:

- Improved Signal Integrity: Reduces unwanted electrical noise, ensuring smooth operation.

- Enhanced Device Performance: Prevents interference from disrupting sensitive circuits.

- Compliance with EMI Standards: Helps meet industry regulations regarding electromagnetic compatibility.

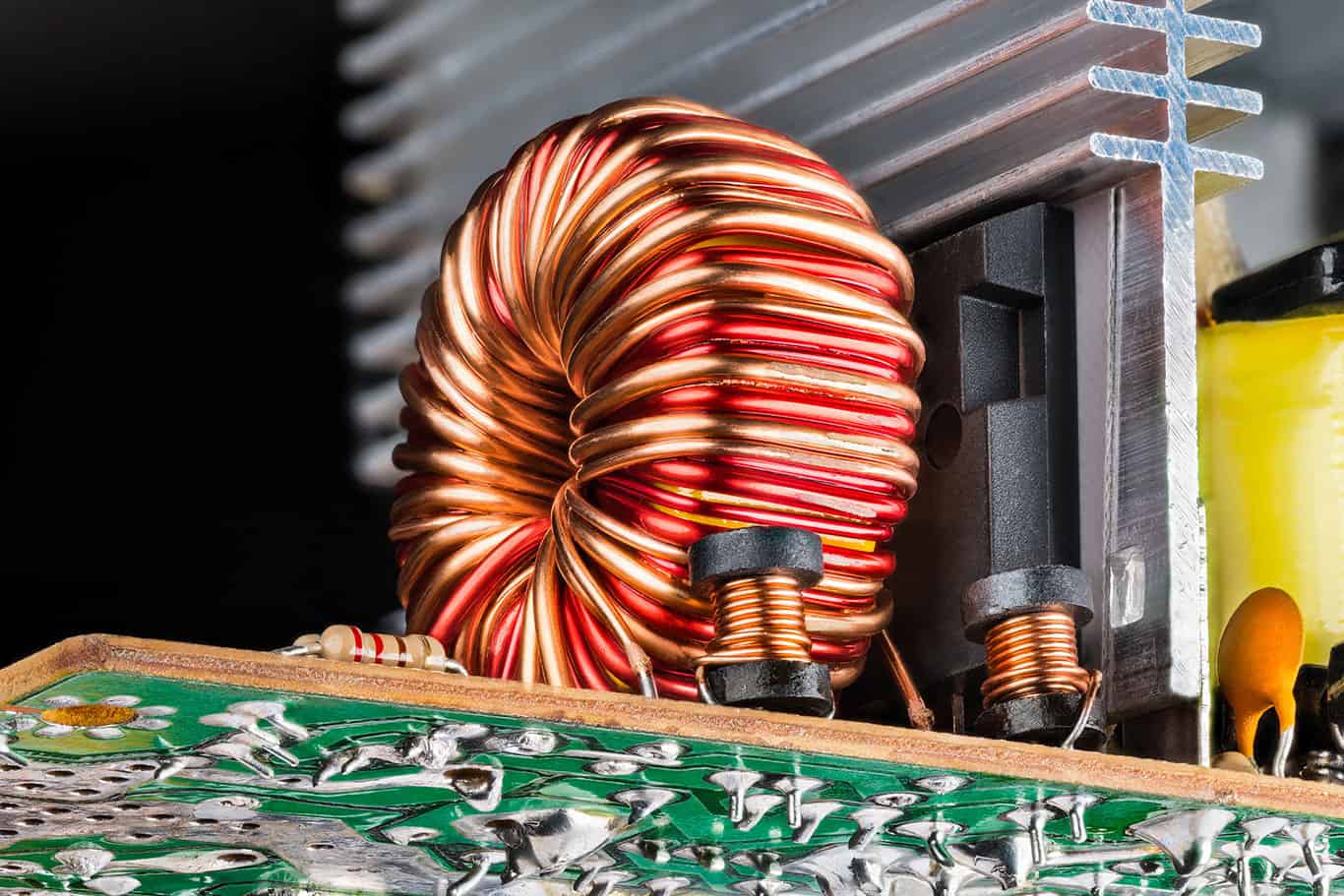

Ferrite Rings in High-Frequency Power Supplies

High-frequency power supplies, such as those used in telecommunications and industrial electronics, demand components that can operate efficiently under rapidly changing currents and voltages. They excel in these environments due to their ability to handle high-frequency signals without energy loss.

Their application in transformers, chokes, and inductors significantly boosts energy efficiency, minimising power dissipation and heat generation. This makes the rings essential for improving overall system reliability and reducing energy consumption in high-power applications.

Why Use Ferrite Rings in Power Supplies?

- Energy Efficiency: Reduces power loss, enhancing the system’s overall performance.

- Heat Reduction: Minimises heat buildup, extending the lifespan of components.

- Compact Design: Allows for smaller, more efficient designs in high-frequency circuits.

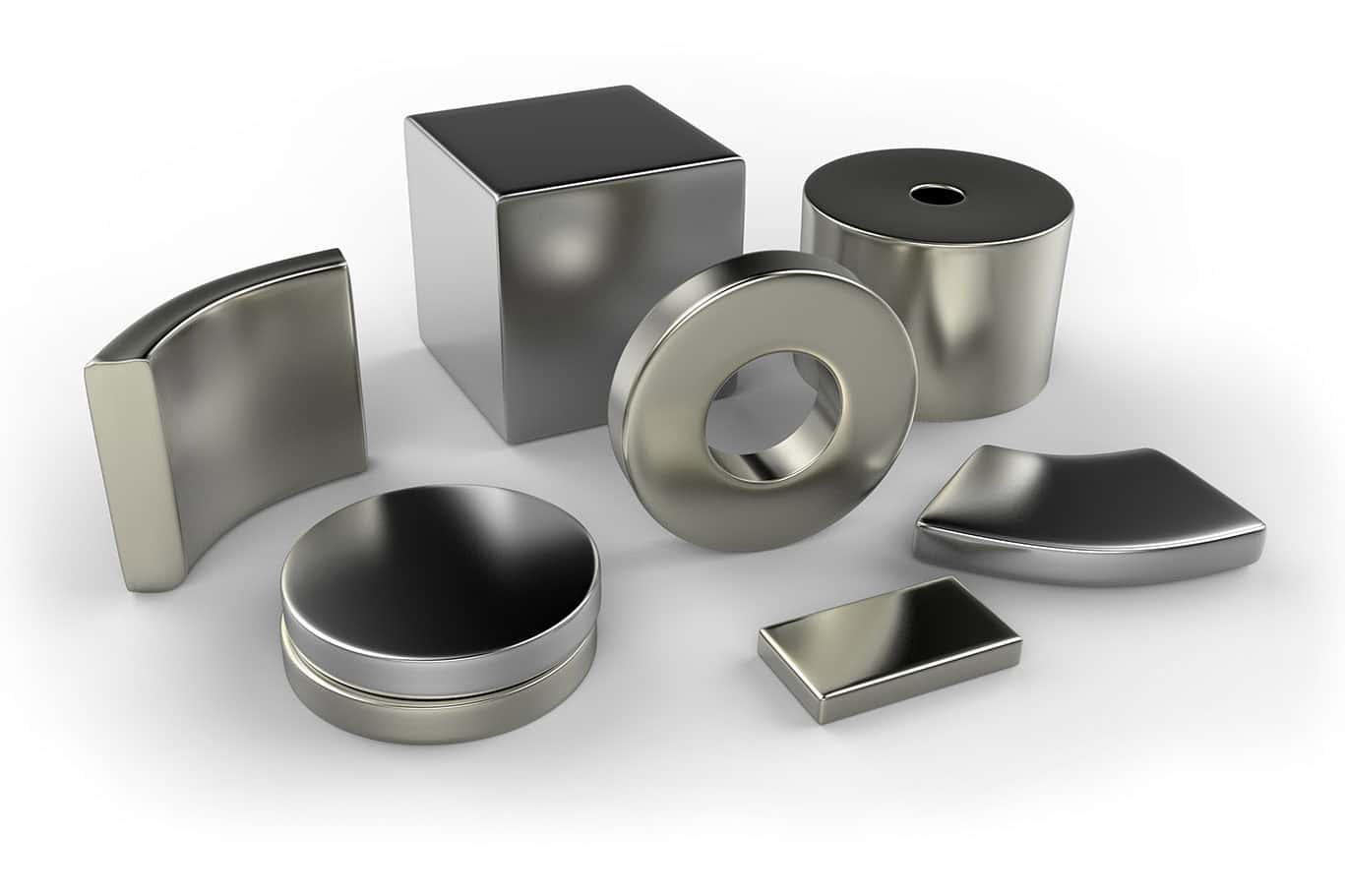

Selecting the Right Ferrite Ring for Your Application

Choosing the right ferrite ring depends on several factors, including the frequency range, power requirements, and type of device. For high-frequency applications, ferrite materials like MnZn (Manganese-Zinc) or NiZn (Nickel-Zinc) are often preferred for their superior magnetic properties. It’s also essential to consider the core size, permeability, and saturation level when selecting a ferrite ring.

For example:

- MnZn Ferrite: Ideal for lower frequencies (below 1 MHz).

- NiZn Ferrite: Best for higher frequencies (above 1 MHz).

By understanding your application’s requirements, you can select the most suitable ferrite ring to optimise performance and reduce unwanted noise.

In conclusion, ferrite rings are indispensable for high-frequency power applications. By effectively reducing electromagnetic interference and boosting system efficiency, they ensure that modern electronic devices operate smoothly without disruptions. Whether in transformers, inductors, or power supplies, the right ring can dramatically enhance performance and longevity.

To find the best ferrite ring for your needs, explore the range of magnetic materials offered by East Manufacturing Technologies Ltd (EMTL). With a wide selection of high-quality ferrite cores, we can help you enhance your power system’s efficiency.

For more information about our ferrite rings and other magnetic materials, contact East Manufacturing Technologies Ltd today.

- Email: sales@emtl.co.uk

- Phone: +44 1462 680689

- Address: East Manufacturing Technologies Ltd, Pixmore Centre, Pixmore Avenue, Letchworth, Hertfordshire, SG6 1JG

Frequently Asked Questions (FAQs)

Q1: What is the main function of a ferrite ring in electronic circuits?

A1: They are primarily used to suppress high-frequency electromagnetic interference (EMI), ensuring smoother operation of electronic circuits by filtering out unwanted noise.

Q2: Can I use the same ferrite ring for all frequency ranges?

A2: No, the type of ferrite material (e.g., MnZn or NiZn) should match the frequency range of your application. Different rings are designed for specific frequencies to optimise performance.

Q3: How do ferrite rings improve energy efficiency in power supplies?

A3: They minimise energy loss by absorbing high-frequency noise, reducing heat buildup, and enhancing the overall efficiency of the power supply system. For more information, check out the official Wikipedia page.