Custom Wound Components:

In the world of electronic circuits, chokes and inductors play pivotal roles in ensuring smooth operation and enhanced performance. These components are crucial for managing electrical signals, suppressing noise, and maintaining power efficiency in a wide range of applications. When designed as custom wound components, chokes and inductors offer even greater precision, tailored specifically to the needs of advanced circuit designs. In this blog, we’ll explore why chokes and inductors are indispensable and how they contribute to more efficient and reliable electronics.

What Are Chokes and Inductors?

Both chokes and inductors are passive components that store energy in a magnetic field when electrical current passes through them. While their functions are similar, their uses vary slightly:

- Inductors are primarily used to manage current flow in circuits, storing energy temporarily and helping to maintain consistent power levels.

- Chokes, a type of inductor, are designed to block or “choke” high-frequency alternating currents while allowing lower-frequency currents to pass through. This makes them essential for reducing electromagnetic interference (EMI).

Key Roles of Chokes and Inductors in Circuit Design

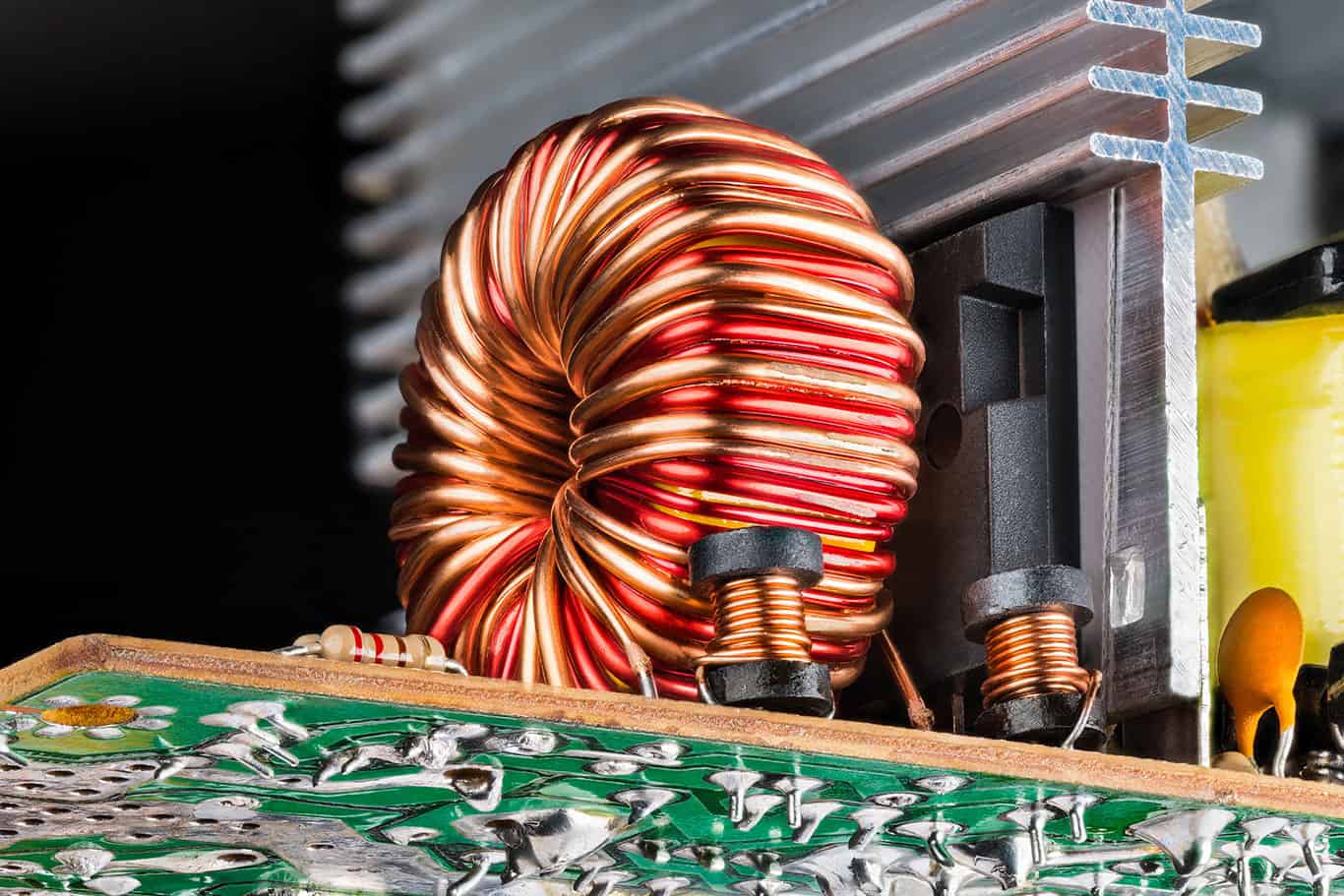

1. Signal Filtering and Noise Suppression

In electronic systems, unwanted noise and interference can disrupt the performance of circuits. Custom wound chokes are commonly used to filter out high-frequency noise, particularly in power supply circuits. By suppressing EMI, they ensure cleaner signals and more reliable operation, especially in sensitive devices such as communication systems, medical equipment, and automotive electronics.

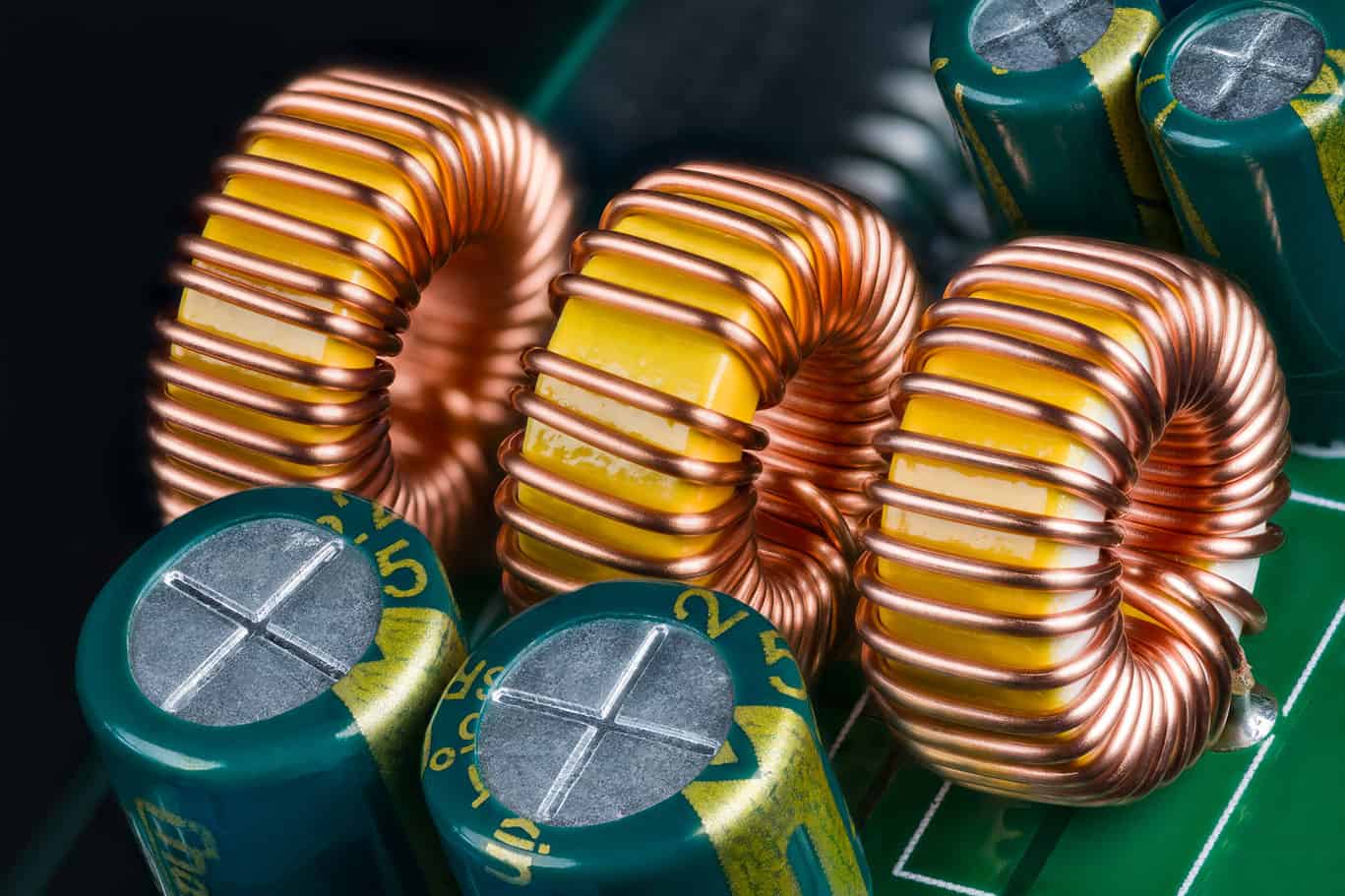

2. Energy Storage and Power Management

Inductors are crucial for energy storage in circuits. They temporarily store electrical energy in a magnetic field and release it when needed, helping to regulate current flow. This function is particularly valuable in power supplies, where inductors help smooth out fluctuations, ensuring a steady and reliable power output. In switching power supplies, inductors play an essential role in improving energy efficiency, reducing heat, and minimising power loss.

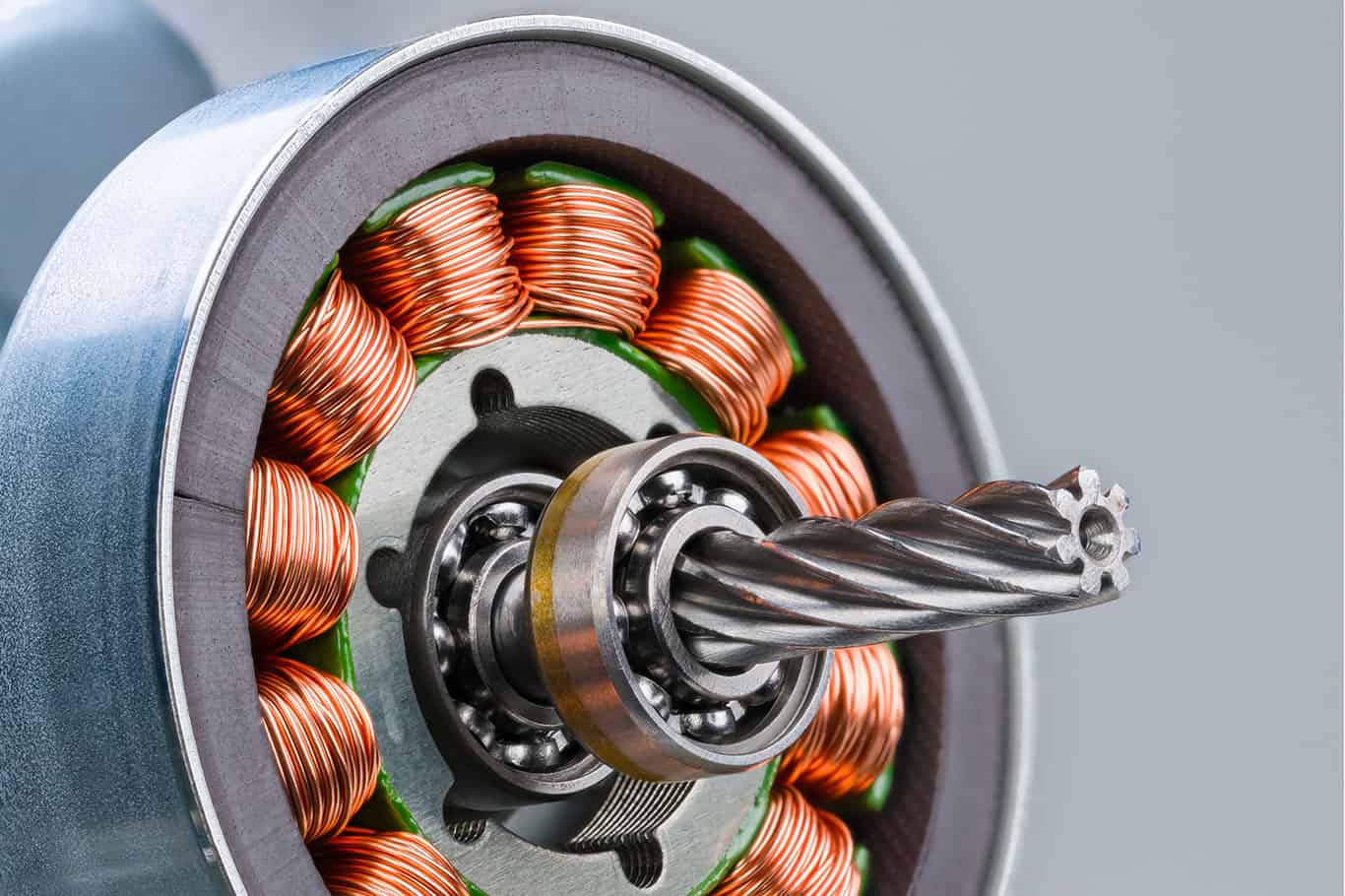

3. Enhancing Circuit Stability

For circuits that handle high currents or require consistent operation, inductors help stabilise the current flow. Custom wound inductors are tailored to specific voltage and current requirements, ensuring that they perform optimally in various conditions. This is especially important in applications like electric vehicle chargers, industrial equipment, and renewable energy systems, where reliable performance is critical.

Custom Wound Components: Tailoring for Precision

While standard chokes and inductors are widely available, custom wound components offer a higher level of precision, designed specifically for the unique needs of a given circuit. At East Manufacturing Technologies Ltd, we specialise in manufacturing custom inductors and chokes for applications covering a huge span of industries, from both our UK and China facilities. Custom wound components are designed with specific core materials, wire gauges, and winding configurations to match the exact electrical and mechanical requirements of the circuit.

Benefits of Custom Wound Chokes and Inductors:

- Optimised Performance: Custom components ensure maximum efficiency and reliability in complex circuit designs.

- Flexibility: Whether you need components for power conditioning, signal processing, or EMI suppression, custom chokes and inductors can be tailored to meet diverse needs.

- Durability: Custom wound components are built to withstand specific operating environments, ensuring long-lasting performance in harsh conditions such as extreme temperatures or heavy industrial use.

Common Applications of Chokes and Inductors

- Power Supplies: Inductors are key in voltage regulation and energy storage in power supplies, making them critical for powering devices ranging from laptops to large industrial machines.

- EMI Suppression: Chokes are indispensable in communication devices, audio equipment, and other electronics where EMI could interfere with signal integrity.

- Transformers and Motors: Custom wound inductors are essential in transformers, ensuring the efficient transfer of electrical energy across various voltages.

- Renewable Energy Systems: With the growing demand for renewable energy, custom inductors play a key role in managing energy flow in solar inverters and wind turbines.

Chokes and inductors are foundational components in circuit design, ensuring stability, power efficiency, and noise suppression. As custom wound components, they offer precision and tailored performance for a wide range of applications, from consumer electronics to industrial power systems. At East Manufacturing Technologies Ltd, our expertise in designing and manufacturing custom inductors and chokes ensures that your circuits perform at their best, no matter how demanding the application.

For more information on our range of custom wound components, visit our wound components page or contact East Manufacturing Technologies Ltd at:

- Email: sales@emtl.co.uk

- Phone: +44 1462 680689

- Address: Pixmore Centre, Pixmore Avenue, Letchworth, Hertfordshire, SG6 1JG

FAQs

Q1: What is the difference between a choke and an inductor?

A1: Both are inductive components, but chokes are specifically designed to filter high-frequency noise, while inductors generally store energy and help regulate current flow.

Q2: Why are custom wound chokes and inductors beneficial?

A2: Custom wound components are tailored to match specific electrical requirements, ensuring optimal performance and efficiency in the given application.

Q3: How do chokes and inductors improve energy efficiency?

A3: Inductors help manage energy flow in circuits, reducing fluctuations and power loss, which leads to improved energy efficiency, especially in power supplies and renewable energy systems.