Ferrite magnets have become one of the most widely used magnetic materials, known for their affordability, durability, and magnetic strength. These magnets are critical in various applications, from household appliances to industrial machines. But what goes into creating these essential components? In this blog, we will take a closer look at the manufacturing process of ferrite magnets and how their unique properties make them indispensable in many industries.

What Are Ferrite Magnets?

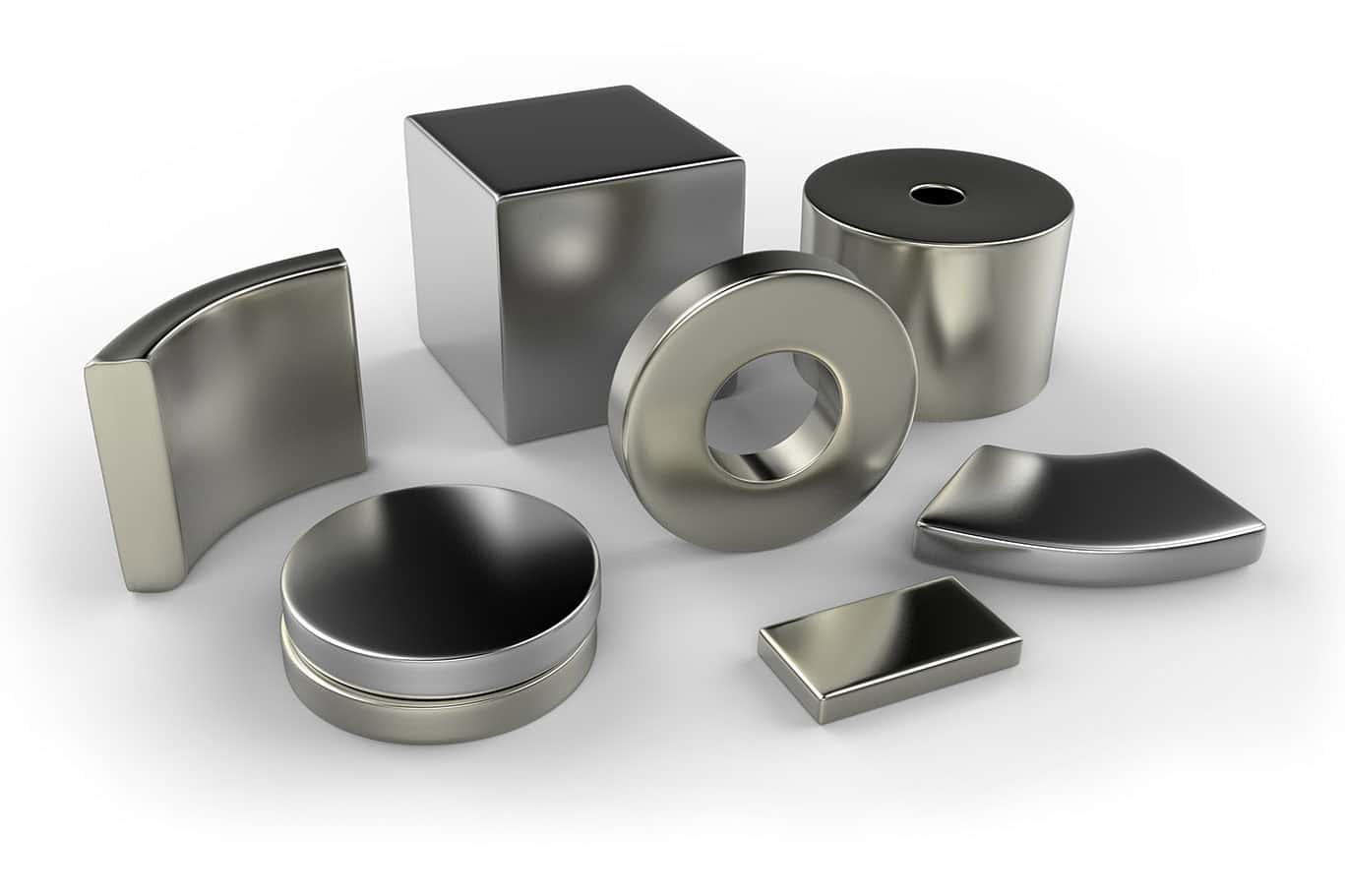

Ferrite magnets, also known as ceramic magnets, are made from a combination of iron oxide (Fe₂O₃) and either barium carbonate (BaCO₃) or strontium carbonate (SrCO₃). They are sintered, meaning the powder materials are heated until they bond without melting. This process results in a strong, durable magnet suitable for both high and low-temperature applications.

Step-by-Step Manufacturing Process of Ferrite Magnets

1. Material Preparation

The first step in manufacturing ferrite magnets is the preparation of raw materials. The two primary components, iron oxide and either barium or strontium carbonate, are carefully selected based on the desired properties of the final magnet. These materials are ground into a fine powder to ensure a homogenous mixture, which is crucial for achieving consistent magnetic properties.

2. Mixing and Milling

The powdered materials are mixed and milled together to create a uniform blend. This milling process breaks down the particles further, ensuring that the iron oxide and carbonate are evenly distributed. The result is a fine, consistent powder that forms the base of the magnet.

3. Pre-Sintering

Once the raw materials are mixed, the powder undergoes a pre-sintering process. This involves heating the mixture at a moderate temperature, which encourages the formation of ferrite crystals. During pre-sintering, the materials do not yet fuse fully but begin to solidify into a more stable form.

4. Forming and Pressing

After pre-sintering, the powder is shaped into the desired form using a die. This is typically done under high pressure to ensure that the particles bond together tightly. The shapes formed during this stage are known as “green bodies,” as they have not yet been fully sintered. At this point, the magnet is still fragile and not magnetised.

5. Final Sintering

The green bodies are then heated in a furnace at temperatures exceeding 1200°C in a process called sintering. During sintering, the particles fuse together, solidifying the magnet and giving it its final shape and structural integrity. The high temperatures also encourage the formation of the ferrite phase, where the magnetic properties develop fully.

6. Magnetisation

Once the sintering process is complete, the ferrite magnets are cooled and ready for magnetisation. In this step, a powerful magnetic field is applied to align the magnetic domains within the material. This is what gives the magnet its permanent magnetic properties. The strength of the magnetic field used in this process determines the final magnetic strength of the ferrite magnet.

7. Finishing and Quality Control

After magnetisation, the ferrite magnets are finished to meet specific size and shape requirements. They may be cut, ground, or polished depending on their intended application. Rigorous quality control checks are performed to ensure that the magnets meet the required standards for magnetic strength, durability, and resistance to environmental factors like temperature and corrosion.

Why Ferrite Magnets Are So Widely Used

The widespread use of ferrite magnets can be attributed to their numerous advantages:

- Cost-Effective: They are cheaper to produce than many other types of magnets, such as neodymium or samarium-cobalt magnets. This makes them ideal for large-scale applications.

- Durable: They are highly resistant to demagnetisation, making them suitable for long-term use in a variety of environments.

- High Temperature Resistance: They can function at high temperatures, often up to 250°C, without significant loss of magnetic strength.

- Corrosion Resistance: Unlike some other magnets, ferrite magnets are naturally resistant to corrosion, which makes them ideal for outdoor and marine applications.

Common Applications of Ferrite Magnets

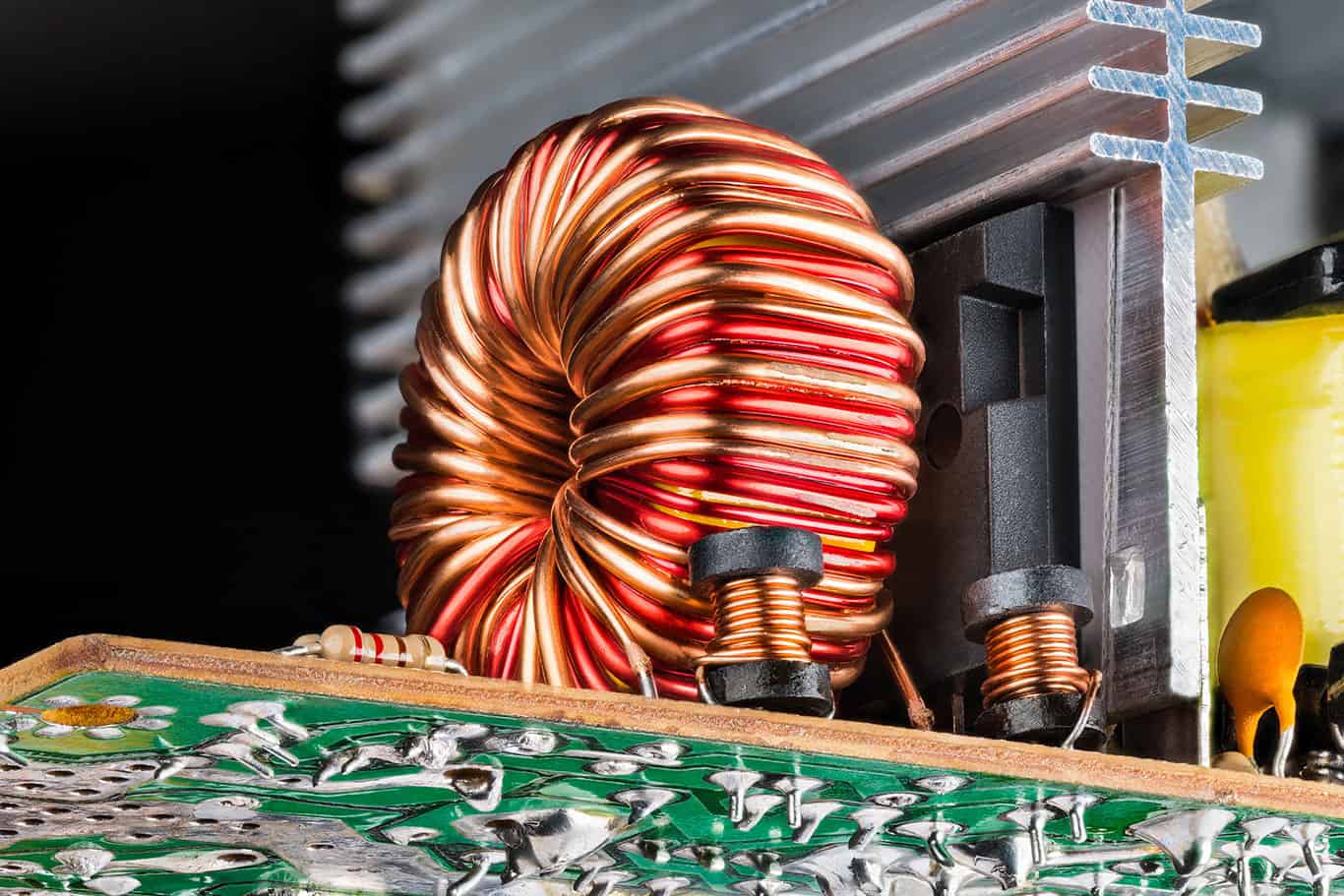

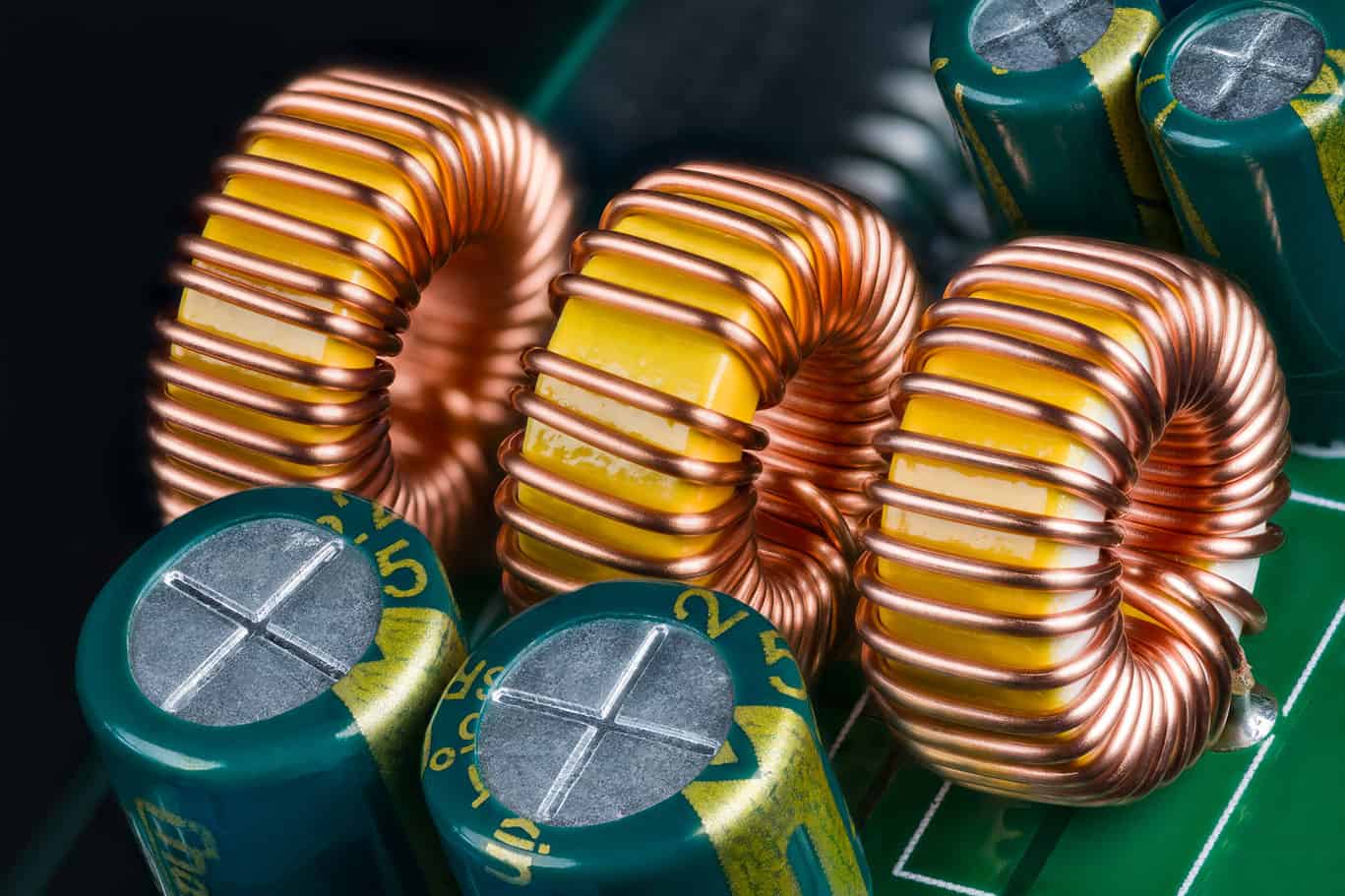

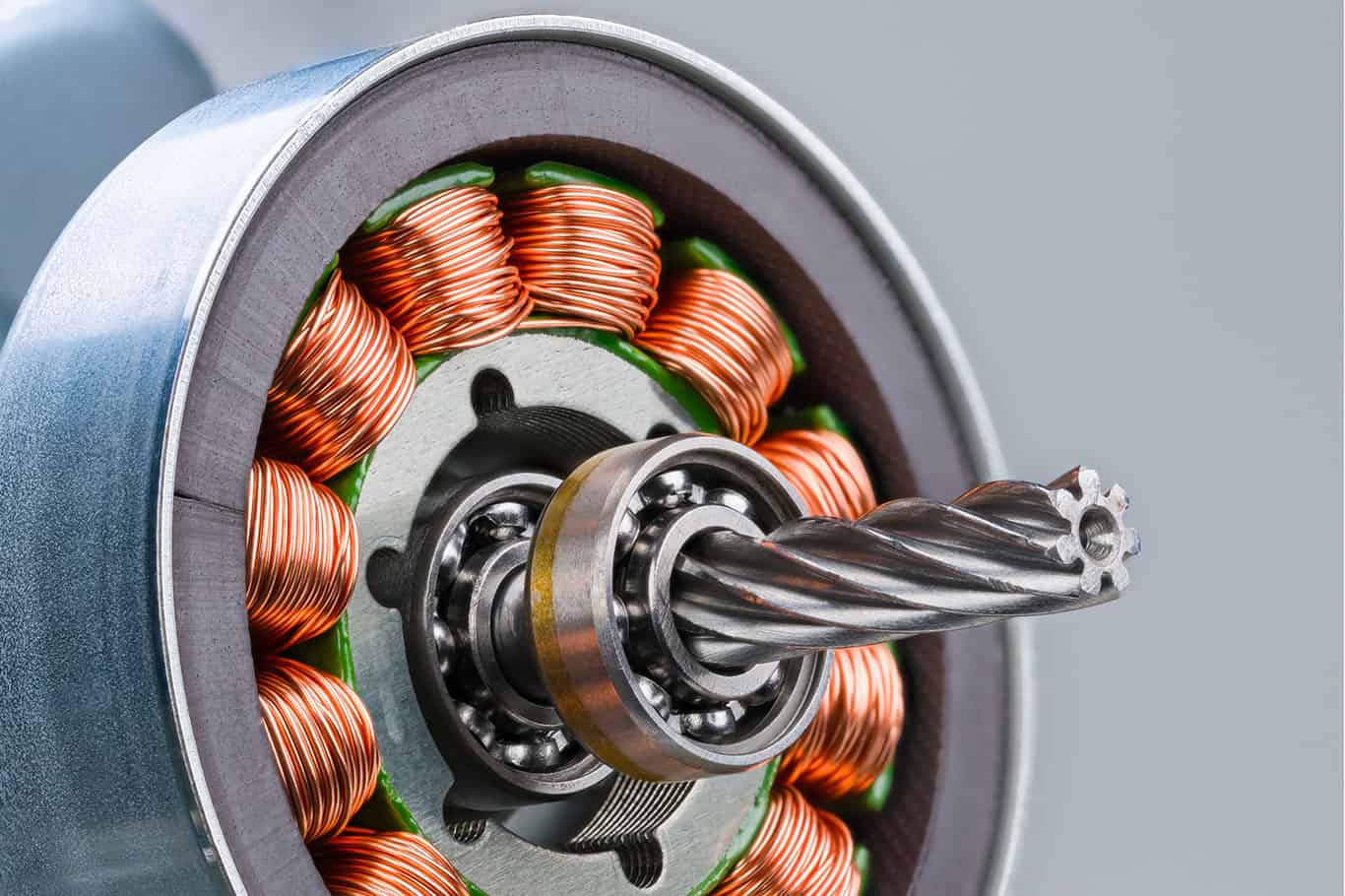

- Motors and Generators: Ferrite magnets are commonly used in electric motors and generators due to their strength and durability.

- Loudspeakers: Many audio devices, including loudspeakers, use ferrite magnets because of their ability to produce clear and consistent sound quality.

- Magnetic Separation: They are often employed in industries for separating magnetic materials from non-magnetic substances, such as in recycling plants.

- Sensors and Switches: Their reliability and affordability make them suitable for use in various sensor technologies and magnetic switches.

- Magnetic Assemblies: They are ideal for applications that require long-lasting magnetic strength and are found in holding devices, magnetic assemblies, and mechanical tools.

The manufacturing process of ferrite magnets involves several intricate steps, from raw material selection and mixing to sintering and magnetisation. These magnets have carved out a significant place in many industries due to their affordability, durability, and reliable magnetic performance. Whether used in motors, loudspeakers, or magnetic separation, ferrite magnets continue to be a cornerstone of modern electronics and industrial systems.

For more information on ferrite magnets and other magnetic materials, visit our magnets page or contact us at East Manufacturing Technologies Ltd for expert guidance and product solutions tailored to your needs.

For any inquiries or to explore our custom magnet solutions, please contact East Manufacturing Technologies Ltd:

- Email: sales@emtl.co.uk

- Phone: +44 1462 680689

Address: Pixmore Centre, Pixmore Avenue, Letchworth, Hertfordshire, SG6 1JG

FAQs

Q1: What materials are used to make ferrite magnets?

A1: Ferrite magnets are made from a combination of iron oxide (Fe₂O₃) and either barium carbonate (BaCO₃) or strontium carbonate (SrCO₃).

Q2: Why are ferrite magnets resistant to corrosion?

A2: Ferrite magnets are naturally resistant to corrosion because of their ceramic-like properties, making them suitable for use in outdoor and marine environments without additional coatings.

Q3: What are the common uses of ferrite magnets?

A3: Ferrite magnets are used in motors, generators, loudspeakers, magnetic separation systems, and various types of sensors and switches.